Integration of CAE Software Enables Visualization of Compression Molding

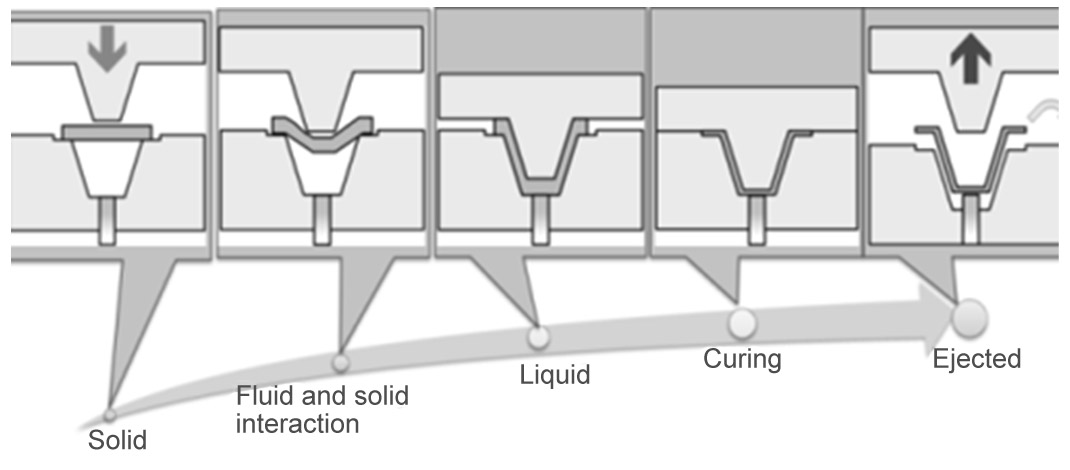

Compression molding is a common process in manufacturing complex composite components for industrial applications (Fig. 1). Â Sheet Molding Compound (SMC), Glass Mat Thermoplastic (GMT), and Pre-Impregnated (Pre-Preg) are the most common compression molding processes used in composite component manufacturing. Â However, since the rheological properties of composite materials have both solid and fluid behaviors, simulation becomes a challenge. Â Commercial softwares are designed to calculate either fluid behavior or structure deformation and those calculations are derived from different equations.

Fig. 1 Compression molding process

Fig. 1 Compression molding process

SMC, formed using compression molding process, can now be analyzed by integrated numerical simulation. The integration method, involving both Computational Structural Mechanics (CSM) and Computational Fluid Dynamics (CFD), is used to predict both charge’s deformation and flow behavior of SMC, respectively.

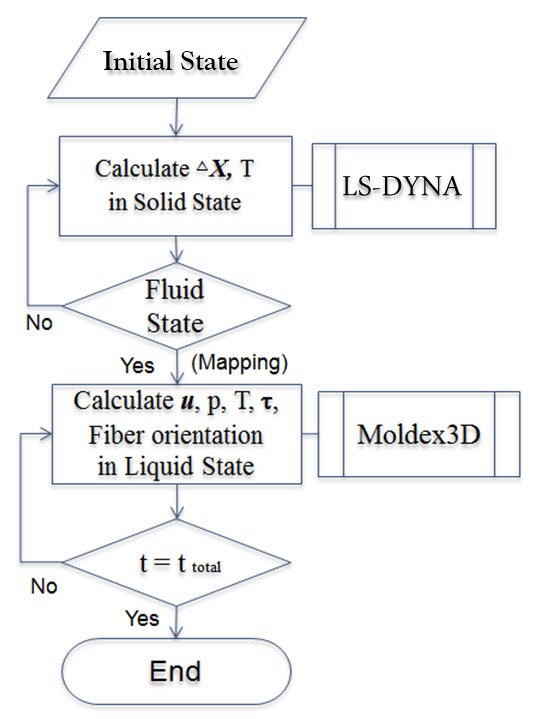

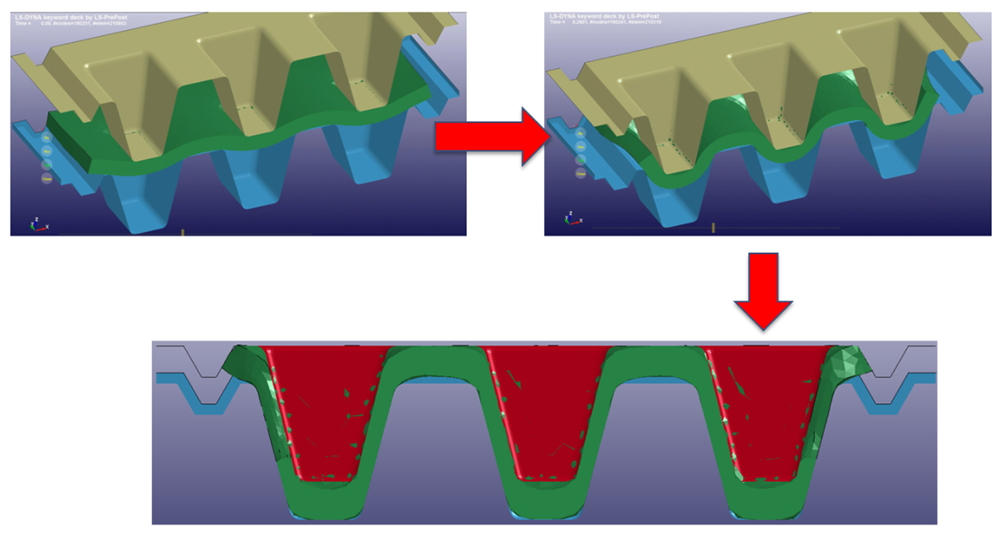

To simulate the process, LS-DYNA, commercially available FEA software, integrated with Moldex3D is applied (Fig. 2). The initial charge’s shape, temperature, stress tensor, and anisotropic material property are first computed by LS-DYNA; then, carrying those physical properties, the deformed charge is exported to Moldex3D to continue the compression molding analysis (Fig. 3). The analysis results of flow behavior and warpage show that the proposed integration method can successful simulate the complex behaviors of SMC in compression molding.

Fig.2 Flowchart of integration method

Fig.2 Flowchart of integration method

Fig. 3 Charge’s deformation during compression is simulated

Fig. 3 Charge’s deformation during compression is simulated

The integration with LS-DYNA is a new feature in Moldex3D R15.0. Through it, the full compression molding process of SMC can be comprehensively and accurately simulated. The charge’s large deformation behavior of SMC is calculated by LS-DYNA, while the fluid behavior and fiber orientation during compression molding is computed by Moldex3D. This enables users to attain more accurate and reliable data for product and process designs easily.

Vacuum forming process is used to produce a variety of parts and components for toys and hobby products, including model cars, airplanes, children drones,and boats. The process allows for the creation of intricate shapes and designs at a relatively low cost.

The characteristics of vacuum forming toys:

1.Lightweight: Vacuum-formed toys are typically lightweight, making them easy for children to handle and play with.

2.Durable: Vacuum-formed toys are made from sturdy materials such as plastic, which makes them durable and able to withstand rough play.

3.Various types and colors. As custom vacuum formed,the toys can be with various types and colors.

4.Cost-effective: Vacuum forming is a cost-effective manufacturing process, making vacuum-formed toys affordable for consumers.

5.Safe: Vacuum-formed toys are typically designed with rounded edges and non-toxic materials, ensuring the safety of children during play

6.Easy to clean: Vacuum-formed toys are easy to clean and maintain, as they can be wiped down with a damp cloth or washed with mild soap and water.

7.Eco-friendly: Vacuum-formed toys can be done using recyclable materials which is environmentally friendly.

Vacuum Formed Toys,Vacuum Forming Service,Custom Vacuum Forming,Vacuum Forming

Dongguan Yiyongli Industrial Co.,Ltd. , https://www.dgthermoforming.com